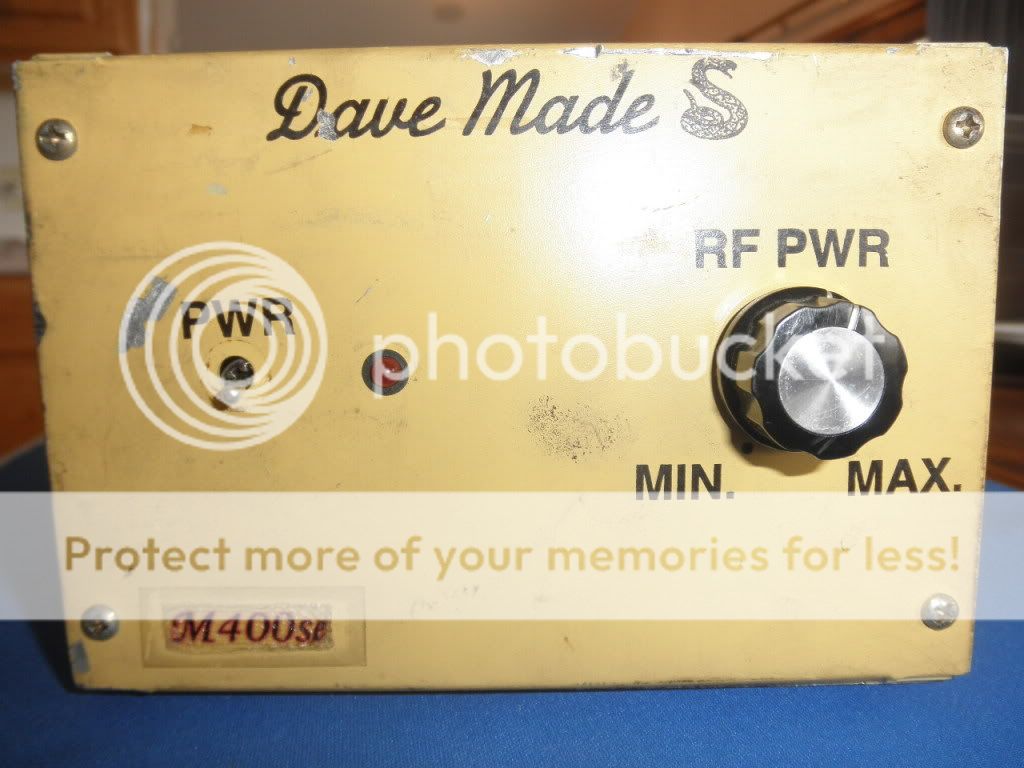

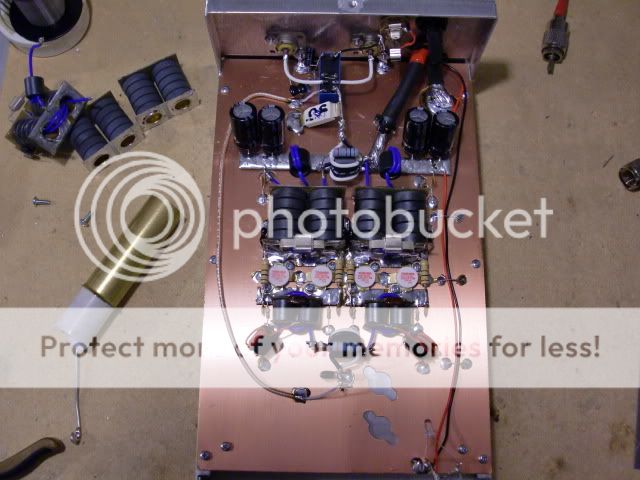

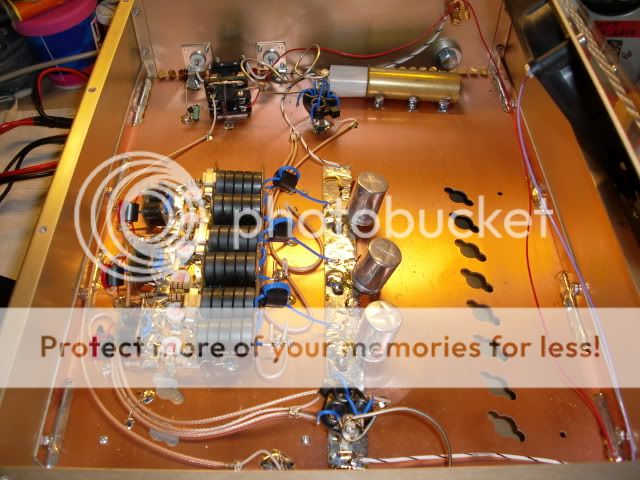

I recently purchased this Dave Made (Model M420SE) 2x4 amp. The seller said this was a Jersey made amp and not a Joe made amp. He and his brother purchased identical amps back in the 80's. I have no reason to doubt him but I will post pics to verify as to where this amp was made, I will have pics later this week as it is being shipped today. Initially it was thought that there were no Jersey Dave Made 2x4 amps but it has been said that special edition 2x4 Jersey amps were indeed built. Stay tuned for this mystery to be solved.

I mostly visit two forums so I thought the traffic flow here might have a different crowd so I thought I would post here also.

Last edited: