THE NEW PHONE BOOKS ARE HERE!

THE NEW PHONE BOOKS ARE HERE!

You can be excused if you don't remember that scene from the Steve Martin film "The Jerk".

But that's how I feel every time the "OOPS" driver arrives with a new batch of blank pc boards.

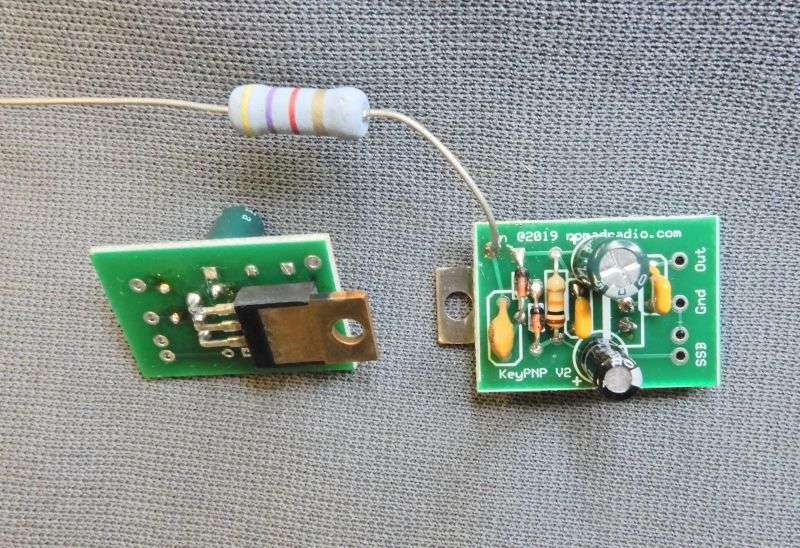

But the real subject of interest is how to keep down the unit cost of small circuit boards. Any of these can be made on a piece of Rat-Shack style perf board. The labor to do it that way costs a lot more, naturally. That's the point of these boards. Reducing the labor to build stuff our customers keep asking for.

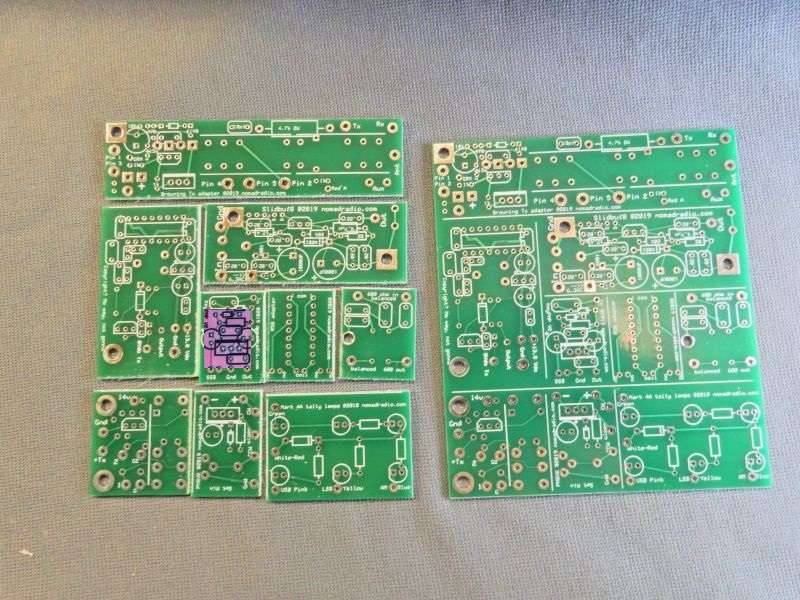

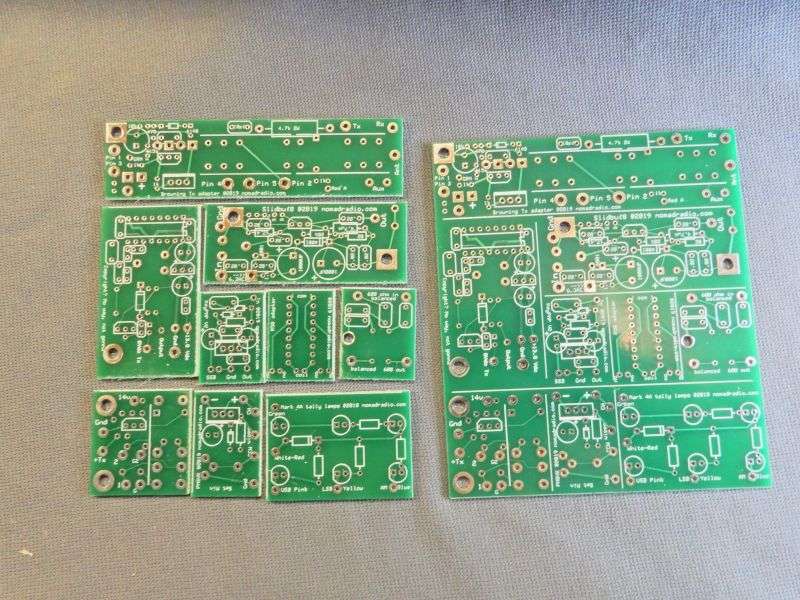

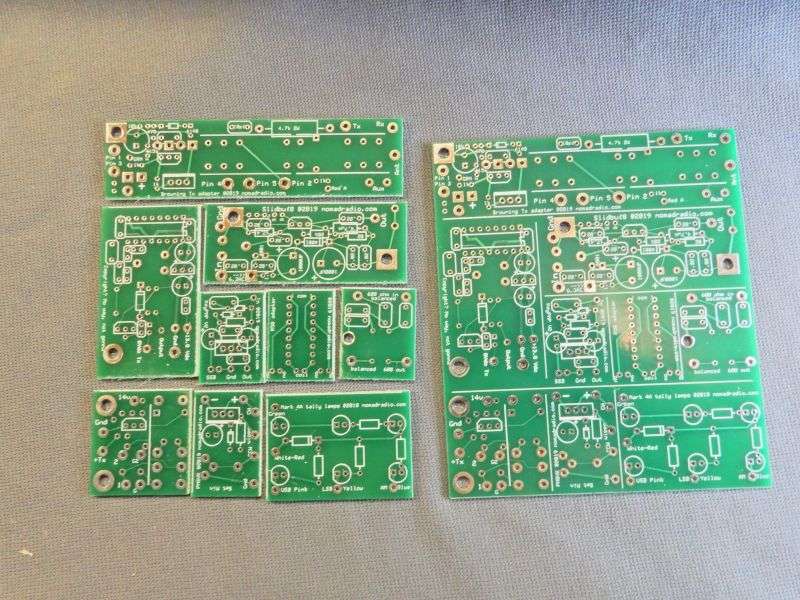

Here's how to keep down the item price of small circuit boards. Cram them onto one larger board, and cut them apart.

This does require eight cuts on our sheet-metal shear for each one, to get the nine gadgets separated. For 50 boards, that makes 400 whacks of the shear.

What was that about saving labor? Yeah, it's a boring exercise, but still less trouble than the perf-board method all in all.

Everything's relative.

Got ten done. 40 more to go. Or is that 320 more to go?

Still beats being the UPS driver who delivered them. At least from where I stand.

Gonna be busy getting 450 boards stuffed and soldered.

73

THE NEW PHONE BOOKS ARE HERE!

You can be excused if you don't remember that scene from the Steve Martin film "The Jerk".

But that's how I feel every time the "OOPS" driver arrives with a new batch of blank pc boards.

But the real subject of interest is how to keep down the unit cost of small circuit boards. Any of these can be made on a piece of Rat-Shack style perf board. The labor to do it that way costs a lot more, naturally. That's the point of these boards. Reducing the labor to build stuff our customers keep asking for.

Here's how to keep down the item price of small circuit boards. Cram them onto one larger board, and cut them apart.

This does require eight cuts on our sheet-metal shear for each one, to get the nine gadgets separated. For 50 boards, that makes 400 whacks of the shear.

What was that about saving labor? Yeah, it's a boring exercise, but still less trouble than the perf-board method all in all.

Everything's relative.

Got ten done. 40 more to go. Or is that 320 more to go?

Still beats being the UPS driver who delivered them. At least from where I stand.

Gonna be busy getting 450 boards stuffed and soldered.

73