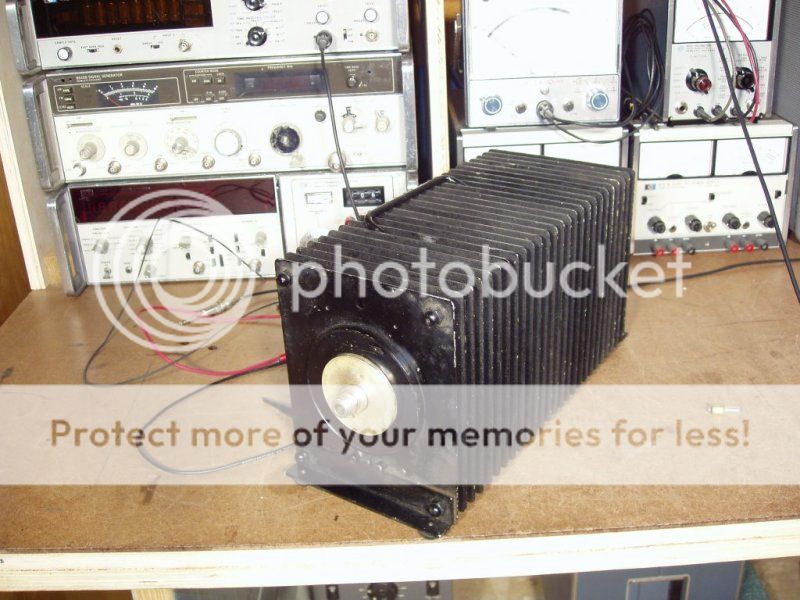

I picked up one of these from Henry Radio with the intention of building an inexpensive, quality dummy load. With no intention of bolting this to a railroad rail for maximum dissipation, I have been pondering what kind of home to build for this without getting too elaborate. All ideas welcome.

New 800 Watt Hybrid 50 ohm Load Resistor to 500 MHz

New 800 Watt Hybrid 50 ohm Load Resistor to 500 MHz

Last edited: