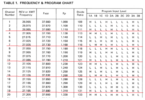

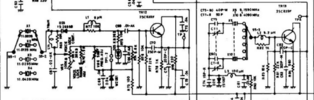

Now i bet you had to look now!, This one is strange but im counting on answers from someone with a good electronic background. So I opened up my 45year old Corba 139 to use DeoxIT and to replace all the burned out lights with led's. So im not sure what i did but put it all back together turned it on and wow lights! it looked good but when i spun the dial i found that i am missing channels 3,7,11,15,19. Now i know some are going to say its a bad crystal,

EXCEPT when i touch one of the solder connections on the back of the channel selector the missing channels come back perfect. The first time it happened it was with a touch of a screwdriver and i thought it was a cold solder joint. So i redid it and no change. It only works when i touch it with the metal part of a screwdriver or if i touch it with a wet finger. Its very cold and the heater been running hard and the air is dry. So im open to ideas???

THANK YOU ALL FOR READING!

EXCEPT when i touch one of the solder connections on the back of the channel selector the missing channels come back perfect. The first time it happened it was with a touch of a screwdriver and i thought it was a cold solder joint. So i redid it and no change. It only works when i touch it with the metal part of a screwdriver or if i touch it with a wet finger. Its very cold and the heater been running hard and the air is dry. So im open to ideas???

THANK YOU ALL FOR READING!