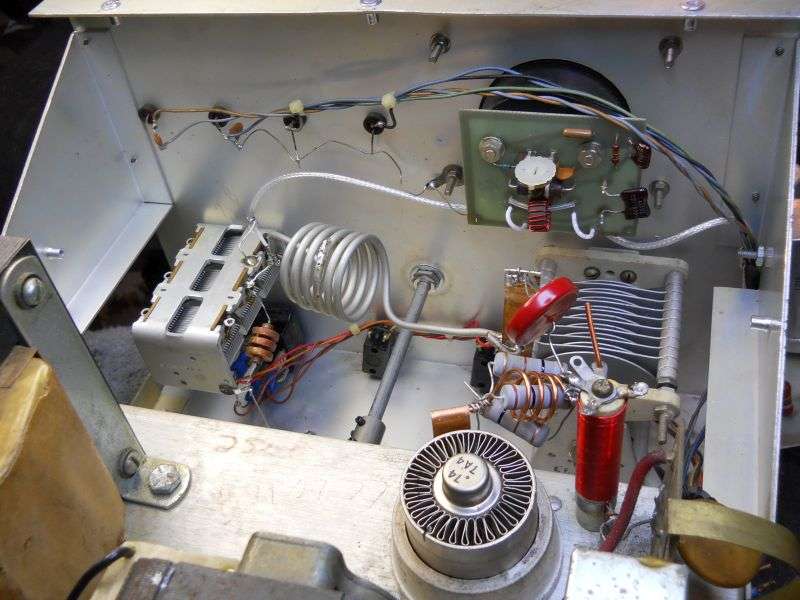

This is becoming a bad habit. Bought another derelict Pride DX300. The older they get, the more derelicts emerge. This one's not so over-the-top as Lazarus. But I paid actual money for it, and I'll need to get the money back out. Puts Lazarus in the back seat for now.

The face of the thing looks okay. Some sketchy stuff is visible in the first pic, but all of it can be corrected.

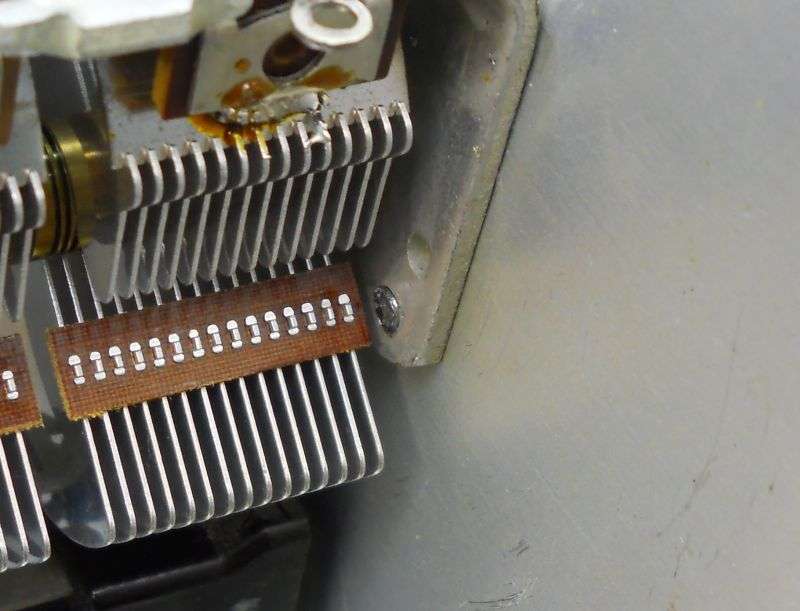

I did stumble across one detail that seemed worth passing along. An exploded ceramic disc capacitor that serves to filter RF energy from escaping out through the power cord.

I call these the "accidental surge protectors". A pulse of lightning energy from the wall socket went to ground through the broken capacitor. Wasn't kind to it. Any time you see this, DO NOT PLUG IT IN until this cap is either removed. Or better, replaced. But it does break down at a voltage low enough the transformers suffered no damage I can identify. Kinda like a real surge suppressor.

People know by now to unplug their coax before a lightning storm, but statistically speaking your antenna is a tiny target if you compare it to the local electric utility's network of wires and poles.

Statistical reality suggest that a nearby utility wire will be struck much more frequently than your one little antenna structure. And when this happens, that lightning energy propagates down the line to your house, if it's within a block or less. A pulse of lightning energy is looking for exactly one thing, the best path to ground it can find. In this example, the disc cap provided that path. The one in the pic is a generic ceramic disc cap. That's pretty well all there was to choose from in 1978. These days, capacitors meant for this kind of use will have safety-agency approval markings on them.

Yeah, things were simpler four-plus decades ago.

And a little more dangerous.

73

The face of the thing looks okay. Some sketchy stuff is visible in the first pic, but all of it can be corrected.

I did stumble across one detail that seemed worth passing along. An exploded ceramic disc capacitor that serves to filter RF energy from escaping out through the power cord.

I call these the "accidental surge protectors". A pulse of lightning energy from the wall socket went to ground through the broken capacitor. Wasn't kind to it. Any time you see this, DO NOT PLUG IT IN until this cap is either removed. Or better, replaced. But it does break down at a voltage low enough the transformers suffered no damage I can identify. Kinda like a real surge suppressor.

People know by now to unplug their coax before a lightning storm, but statistically speaking your antenna is a tiny target if you compare it to the local electric utility's network of wires and poles.

Statistical reality suggest that a nearby utility wire will be struck much more frequently than your one little antenna structure. And when this happens, that lightning energy propagates down the line to your house, if it's within a block or less. A pulse of lightning energy is looking for exactly one thing, the best path to ground it can find. In this example, the disc cap provided that path. The one in the pic is a generic ceramic disc cap. That's pretty well all there was to choose from in 1978. These days, capacitors meant for this kind of use will have safety-agency approval markings on them.

Yeah, things were simpler four-plus decades ago.

And a little more dangerous.

73