I'm sure the answer to this question is buried in this forum somewhere, but I had minimal luck turning it up. My question: what I say involved in converting some of my Maco 200's to 6 volt? I understand I have to reduce the filament voltage to 6.3 volts, but is there anything else involved? I've read about tube neutralization and keeping the tubes in even numbers. The 200 wouldn't be hard to do with 4 tubes I wouldn't think. I've got drawers full of 6 volt tubes, and I'm not really interested in buying more 8950's for obvious reasons. Thanks for any direction

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

12 volt to 6 volt tube conversion

- Thread starter dozerman

- Start date

dozerman,

Below is copied and pasted from Ken's Electronics web site. (Good site full of info but can be hard to decipher)

"8950 & M2057: Obsolete 12 volt duodecar tubes; In most cases the heater pins can be rewired in series-parallel to use similar 6 Volt tubes such as 6KD6, 6LF6, 6LX6, or 6MH6."

Getting the correct filament voltage to your new 6 volt tubes is the easy part.

New sockets will be involved to accommodate the 6 volt tubes.

I would think that circuit value changes (input matching, output loading etc) will also be required to accommodate your new tubes-perhaps even HV to the plate?

I am sure there are those on this forum who have done this in the past and will chime in.

Good Luck.

73's

David

Below is copied and pasted from Ken's Electronics web site. (Good site full of info but can be hard to decipher)

"8950 & M2057: Obsolete 12 volt duodecar tubes; In most cases the heater pins can be rewired in series-parallel to use similar 6 Volt tubes such as 6KD6, 6LF6, 6LX6, or 6MH6."

Getting the correct filament voltage to your new 6 volt tubes is the easy part.

New sockets will be involved to accommodate the 6 volt tubes.

I would think that circuit value changes (input matching, output loading etc) will also be required to accommodate your new tubes-perhaps even HV to the plate?

I am sure there are those on this forum who have done this in the past and will chime in.

Good Luck.

73's

David

yeah ive read that passage during a google search. also read one where someone converted a Swan with a pair of 8950's to 6lb6's. he just re wired the heater to a series and claimed that was it. i was under the understanding that the tube sockets would all be the same, meaning the 8950 sockets would accommodate the lb6,lf6,kd6 and so on. of course, i am probably wrong about that. i do have new sockets i just bought from John Boy in memphis, if i do need to change them..

About 20 years ago it was pretty common to change Maco's to 6LB6's. Prices were more reasonable then than for 8950's. I would imagine that to be the same nowadays. Availability of 6LB6's now??? Prices now???

I would have to check the Tube Datasheet to be sure but going from memory, the 8950 is a 12 pin tube with a plate cap and the 6LB6 is a 9 pin tube with a plate cap. Someone more knowledgeable than me would have to advise on the circuit differences between the 2 tubes and the supporting components (tank coil, variable capacitor).

I would not expect it to be a "bolt in" affair. Changing filament voltage, installing the correct socket for the tube and high voltage requirement of the chosen tube I would think to be just a small part. Having the amp load and tune correctly, proper input SWR, tubes running at the correct temperature (i.e. not HOT), preventing self oscillation/plate choke and proper circuit safeties in place are all things that must be sorted when making a major "design change".

I'm sure there are those on this forum that have done this in the past and will have recommendations and/or warnings.

73's

David

I would have to check the Tube Datasheet to be sure but going from memory, the 8950 is a 12 pin tube with a plate cap and the 6LB6 is a 9 pin tube with a plate cap. Someone more knowledgeable than me would have to advise on the circuit differences between the 2 tubes and the supporting components (tank coil, variable capacitor).

I would not expect it to be a "bolt in" affair. Changing filament voltage, installing the correct socket for the tube and high voltage requirement of the chosen tube I would think to be just a small part. Having the amp load and tune correctly, proper input SWR, tubes running at the correct temperature (i.e. not HOT), preventing self oscillation/plate choke and proper circuit safeties in place are all things that must be sorted when making a major "design change".

I'm sure there are those on this forum that have done this in the past and will have recommendations and/or warnings.

73's

David

dozerman,

I was wrong. A 6LB6 and an 8950/M2057 are both 12 pin tubes with a plate cap. I should have checked the data sheet first. (Datasheets attached)

https://frank.pocnet.net/sheets/191/6/6LB6.pdf

https://frank.pocnet.net/sheets/084/m/M2057.pdf

My apologies.

73's

David

I was wrong. A 6LB6 and an 8950/M2057 are both 12 pin tubes with a plate cap. I should have checked the data sheet first. (Datasheets attached)

https://frank.pocnet.net/sheets/191/6/6LB6.pdf

https://frank.pocnet.net/sheets/084/m/M2057.pdf

My apologies.

73's

David

dozerman,

I was wrong. A 6LB6 and an 8950/M2057 are both 12 pin tubes with a plate cap. I should have checked the data sheet first. (Datasheets attached)

https://frank.pocnet.net/sheets/191/6/6LB6.pdf

https://frank.pocnet.net/sheets/084/m/M2057.pdf

My apologies.

73's

David

Yeah the 6lq6 would be a 9 pin example but the LB6 and such are 12 pin. I've got a bunch of these 12 pin and several 200's, so I'm gonna convert at least one to see what the fuss is about.

Converting from 8950/2057 tubes to the 6.3-Volt heater substitutes is simpler than it sounds.

You just need an even number of tubes. Either two or four, in this case. The Maco 200 was built more than one way. Don't know how many tube sockets your version has.

You need only to wire pairs of tube heaters in series to use the built-in heater winding on the power transformer.

And a box with only one tube can be converted by placing a 6-Amp rectifier diode in series with the heater pin on the tube socket. This will get you half the averaged-out voltage.

73

You just need an even number of tubes. Either two or four, in this case. The Maco 200 was built more than one way. Don't know how many tube sockets your version has.

You need only to wire pairs of tube heaters in series to use the built-in heater winding on the power transformer.

And a box with only one tube can be converted by placing a 6-Amp rectifier diode in series with the heater pin on the tube socket. This will get you half the averaged-out voltage.

73

Never hurts to check the base-wiring diagram for each tube before applying power. The 12-pin types all use pins 1 and 12 for the heater, the pin on each side of the gap.

But some of the grid pins may be a little different from one type to the next. The base diagram will reveal any other change needed for the socket wiring.

My favorite go-to site for tube data is Frank's http://www.mif.pg.gda.pl/homepages/frank/vs.html

73

But some of the grid pins may be a little different from one type to the next. The base diagram will reveal any other change needed for the socket wiring.

My favorite go-to site for tube data is Frank's http://www.mif.pg.gda.pl/homepages/frank/vs.html

73

Converting from 8950/2057 tubes to the 6.3-Volt heater substitutes is simpler than it sounds.

You just need an even number of tubes. Either two or four, in this case. The Maco 200 was built more than one way. Don't know how many tube sockets your version has.

You need only to wire pairs of tube heaters in series to use the built-in heater winding on the power transformer.

And a box with only one tube can be converted by placing a 6-Amp rectifier diode in series with the heater pin on the tube socket. This will get you half the averaged-out voltage.

73

All of mine are 1x3 with 8950's. I was looking at the data sheets on those and the LF6's and aside from an internal connection on the 8950, they look the same. And I think the LF6 has about 7 watts more peak plate dissipation, with a slightly higher amperage draw. I'm gonna try one tonight and see how it goes.

Never hurts to check the base-wiring diagram for each tube before applying power. The 12-pin types all use pins 1 and 12 for the heater, the pin on each side of the gap.

But some of the grid pins may be a little different from one type to the next. The base diagram will reveal any other change needed for the socket wiring.

My favorite go-to site for tube data is Frank's http://www.mif.pg.gda.pl/homepages/frank/vs.html

73

Just to be sure, which ever tube I start at, I start at #1 then # 1 to the next and out of #12 of the same one to #1 of the next and so on until I finish with the last tube #12 going to ground. Correct?

Well, it's really easier than it seems. Don't know why I've not done this before. Only thing that's weird to me is pin 1 on the tubes have 13.6 volts and pin 12 has 6.3. Operates very well. Seems like it needs more capatance in the load, it's almost fully meshed. But does well. Thanks for all the input fellas!

dozerman,

I'm glad it worked out for you! This type of "mod" breathes a new life into these classic amps at a reasonable price.

Sorry I gave you some misleading information early on.

Pin 12 will show half of Pin 1's input because of the voltage drop across "Tube 1's" filament. Pin 12 (of "Tube 1" )should then hook to pin 1 of the next series/parallel pair(call it "Tube 2"). Pin 12 of the second tube in the pair should return to the (as of yet unused) other filament wire from the transformer.

The process then starts over again with the next series/parallel pair ("Tube 3" & "Tube 4").

It seems to me that you can change the tap point of the tank coil to change the "mesh" point of the load capacitor. I am not trained in this type of work nor do I have the equipment to properly test my "hair brained theories". But I have tinkered with these addictive electronic boxes for about 45 years and can sometimes recall a thing or two-and again THIS MAKES ME NO EXPERT

Again, more experienced and knowledgeable guys should chime in on this.

73's

David

I'm glad it worked out for you! This type of "mod" breathes a new life into these classic amps at a reasonable price.

Sorry I gave you some misleading information early on.

Pin 12 will show half of Pin 1's input because of the voltage drop across "Tube 1's" filament. Pin 12 (of "Tube 1" )should then hook to pin 1 of the next series/parallel pair(call it "Tube 2"). Pin 12 of the second tube in the pair should return to the (as of yet unused) other filament wire from the transformer.

The process then starts over again with the next series/parallel pair ("Tube 3" & "Tube 4").

It seems to me that you can change the tap point of the tank coil to change the "mesh" point of the load capacitor. I am not trained in this type of work nor do I have the equipment to properly test my "hair brained theories". But I have tinkered with these addictive electronic boxes for about 45 years and can sometimes recall a thing or two-and again THIS MAKES ME NO EXPERT

Again, more experienced and knowledgeable guys should chime in on this.

73's

David

dozerman,

Re-reading post #11, it seems you may be a bit confused about series/parallel filament wiring.

Just to be as clear as possible, the way the above is written would be strictly series wired filaments. If your 4 tubes were wired in this manner, the 3rd and 4th tube in the series would have 0 voltage on the filament. (Experts, Please chime in!)

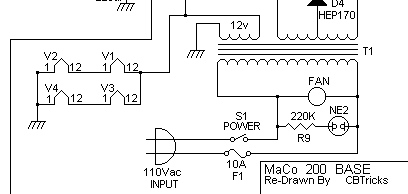

See the filament wiring section below of the following link from CBTricks. It is a Maco 200B with 6LB6's.

http://www.cbtricks.com/Amp/maco/maco_200b/graphics/maco_200b_redraw_sch.gif

V1 & V2 above are in Series with V3 & V4 also in series but parallel to V1 & V2. Or Series/Parallel. (This is what I meant by referencing "Tube 1, Tube 2" etc in post #13.)

Please don't misunderstand my intentions. I am not trying to be "Holier Than Thou" or anything like that. I make my share of mistakes (See post #4 and about every other post I have made! ) Comes with the Old Age thing. Computing with one hand is very slow and chockfull of do overs! I tend to believe my memory instead of researching due to the cumbersome task with my limited ability. (In other words-"Classic Laziness!)

) Comes with the Old Age thing. Computing with one hand is very slow and chockfull of do overs! I tend to believe my memory instead of researching due to the cumbersome task with my limited ability. (In other words-"Classic Laziness!)

I believe wiring all 4 of these tubes in Series and turning on the high voltage may fry at least 2 of your "cheaper" replacements for the 8950/M2057. Last I knew these 6LB6's were about $40.00 each! Too rich for my wallet.

AND

ABOVE ALL ELSE-BE VERY AWARE OF THE HIGH VOLTAGES IN THIS UNIT! PROTECT YOURSELF AT ALL TIMES WHEN WORKING ON THIS UNIT! DISCHARGE THE CAPS, PULL THE FUSE AND PUT THE POWER CORD PLUG END IN YOUR POCKET TO BE SURE YOU ARE SAFE!

I have been lucky enough in the past to survive unscathed a 400vdc jolt (from all else-the awesome Golden Eagle Mark lll). It wasn't pleasant and I vowed not to repeat that stupid mistake. The best lessons learned are taught by repetition and/or Trauma Impact!

Please also seek advice from some experts. There are many of them on this forum. I am not one of them. Just a lucky Old Dude who is still kicking despite all the Trauma Impact lessons I have learned in life.

Have fun, Good Luck and Learn Things!

73's

David

Re-reading post #11, it seems you may be a bit confused about series/parallel filament wiring.

I start at #1 then # 1 to the next and out of #12 of the same one to #1 of the next and so on until I finish with the last tube #12 going to ground. Correct?

Just to be as clear as possible, the way the above is written would be strictly series wired filaments. If your 4 tubes were wired in this manner, the 3rd and 4th tube in the series would have 0 voltage on the filament. (Experts, Please chime in!)

See the filament wiring section below of the following link from CBTricks. It is a Maco 200B with 6LB6's.

http://www.cbtricks.com/Amp/maco/maco_200b/graphics/maco_200b_redraw_sch.gif

V1 & V2 above are in Series with V3 & V4 also in series but parallel to V1 & V2. Or Series/Parallel. (This is what I meant by referencing "Tube 1, Tube 2" etc in post #13.)

Please don't misunderstand my intentions. I am not trying to be "Holier Than Thou" or anything like that. I make my share of mistakes (See post #4 and about every other post I have made!

I believe wiring all 4 of these tubes in Series and turning on the high voltage may fry at least 2 of your "cheaper" replacements for the 8950/M2057. Last I knew these 6LB6's were about $40.00 each! Too rich for my wallet.

AND

ABOVE ALL ELSE-BE VERY AWARE OF THE HIGH VOLTAGES IN THIS UNIT! PROTECT YOURSELF AT ALL TIMES WHEN WORKING ON THIS UNIT! DISCHARGE THE CAPS, PULL THE FUSE AND PUT THE POWER CORD PLUG END IN YOUR POCKET TO BE SURE YOU ARE SAFE!

I have been lucky enough in the past to survive unscathed a 400vdc jolt (from all else-the awesome Golden Eagle Mark lll). It wasn't pleasant and I vowed not to repeat that stupid mistake. The best lessons learned are taught by repetition and/or Trauma Impact!

Please also seek advice from some experts. There are many of them on this forum. I am not one of them. Just a lucky Old Dude who is still kicking despite all the Trauma Impact lessons I have learned in life.

Have fun, Good Luck and Learn Things!

73's

David

Maco was famous for using wimpy, too-small Load controls.

Adding a disc capacitor in parallel with it will help, but only if it's big enough to take the current. You won't find that number printed on it, but higher-voltage disc caps, like 3000-Volt rated types have more metal in them. A cap that doesn't have enough metal in it will overheat and fail. A value around 100pf is a good place to start. Making it much larger than 150 pf may create the opposite situation, with the peak setting at the full-minimum end of travel. Your mileage may vary.

The Plate Tune control is the one to pay attention to. If the plates are near center when it's peaked for max output, you're good to go. And if that control goes all the way to one end or the other, that indicates the need to adjust the coil, and bring the peak position on the Tune control back into range between the max and min extremes.

Just be nice to that Load control. The spacing between the plates is so small, they're easy to bump and throw the plates out of parallel alignment.

73

Adding a disc capacitor in parallel with it will help, but only if it's big enough to take the current. You won't find that number printed on it, but higher-voltage disc caps, like 3000-Volt rated types have more metal in them. A cap that doesn't have enough metal in it will overheat and fail. A value around 100pf is a good place to start. Making it much larger than 150 pf may create the opposite situation, with the peak setting at the full-minimum end of travel. Your mileage may vary.

The Plate Tune control is the one to pay attention to. If the plates are near center when it's peaked for max output, you're good to go. And if that control goes all the way to one end or the other, that indicates the need to adjust the coil, and bring the peak position on the Tune control back into range between the max and min extremes.

Just be nice to that Load control. The spacing between the plates is so small, they're easy to bump and throw the plates out of parallel alignment.

73

dxChat

- No one is chatting at the moment.

-

-

@ heartbreaker3473:Hello gentlemen and Ladies. I have the dreaded RCI-2990 receive issue where my radio gets distorted when people get close to my location. I found the C90 Capacitor, but I can not for the life of me find the C89 capacitor. Can or does anyone have a picture of the exact location of C89 ? Thank you in advance, Wes

-

@ AudioShockwav:Wes, it's better if you start a thread on the main forum, more people are going to see your question.

-

-

@ heartbreaker3473:I put it in the general disscution help area and started a new thread. Thank you for letting me know.