My intuition about the 'SNAP!" would be a tube with gas in the vacuum.

Or a loose grid wire that only touches the cathode intermittently. Tough to find without a continuity tester fast enough to respond, clipped between one grid and one cathode pin. We use our 'octopus', slapping the tube gently on the side, turning it from vertical to sideways. The CRT display is fast enough that even a brief short from a loose grid wire is visible.

Here's the approach we chose to use a Heathkit SB1000 as a tube tester.

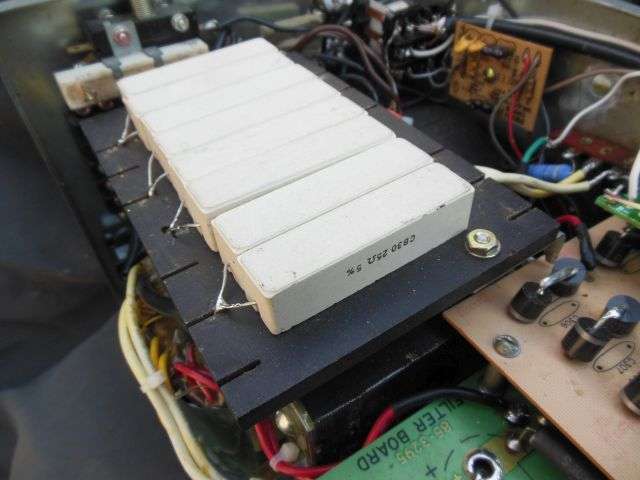

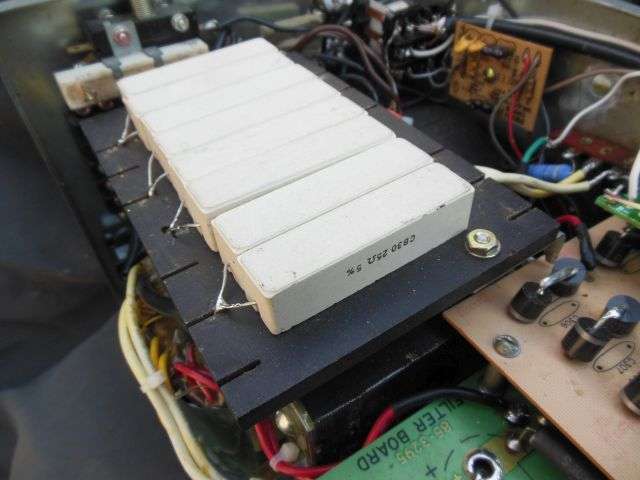

The original 3-Amp rated HV rectifiers got upgraded to 6-Amp parts. The eight 25-ohm 30-Watt resistors add up to 200 ohms in series with the plate supply. It will drop less than 100 Volts max from the HV that reaches the tubes in normal use. It limits the surge current from a 3000-Volt source to 15 Amps, not enough to damage the rectifiers so long as the circuit breaker trips fast enough. The total 240-Watt rating of eight resistors isn't valid to load them that way with steady current. Crowding them together like this reduces the exposed surface area. All they're meant to do is take a very brief overload in stride.

Eimac says that to protect the 3-500Z you should limit the current into any pin of the tube to about that value.

But it's really about protecting the amplifier from a tube, not protecting the tube itself.

It's handy for finding out how "weak" a tube really is when run by itself.

73

Or a loose grid wire that only touches the cathode intermittently. Tough to find without a continuity tester fast enough to respond, clipped between one grid and one cathode pin. We use our 'octopus', slapping the tube gently on the side, turning it from vertical to sideways. The CRT display is fast enough that even a brief short from a loose grid wire is visible.

Here's the approach we chose to use a Heathkit SB1000 as a tube tester.

The original 3-Amp rated HV rectifiers got upgraded to 6-Amp parts. The eight 25-ohm 30-Watt resistors add up to 200 ohms in series with the plate supply. It will drop less than 100 Volts max from the HV that reaches the tubes in normal use. It limits the surge current from a 3000-Volt source to 15 Amps, not enough to damage the rectifiers so long as the circuit breaker trips fast enough. The total 240-Watt rating of eight resistors isn't valid to load them that way with steady current. Crowding them together like this reduces the exposed surface area. All they're meant to do is take a very brief overload in stride.

Eimac says that to protect the 3-500Z you should limit the current into any pin of the tube to about that value.

But it's really about protecting the amplifier from a tube, not protecting the tube itself.

It's handy for finding out how "weak" a tube really is when run by itself.

73

Last edited: