Thanks - came across this while digging - so I can update, the 5.1V though sounds high. If I remember the divider needed to b about 3 V like the earlier issues with the ERF2030 and IRF5020 -

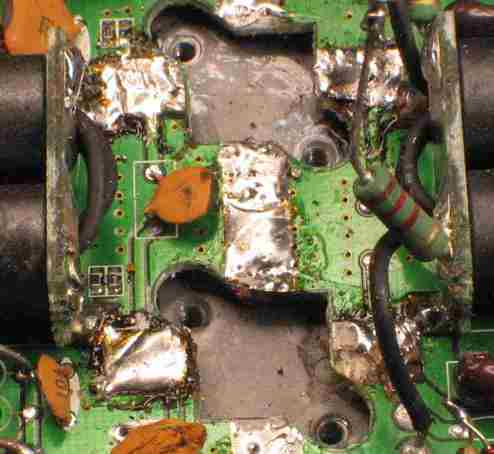

if you notice, the voltage divider resistors were also affected - the ground side ones were missing - or the Gate was set up with no divider at all - power was cut only to the plus side. Making these things set up to blow on the spot once someone tweaked them - which is what happened in my brothers radio.

Someone had worked on it before and "shorted" the wipers of the pot - in the above that would be RV 21 - so the thing saw a constant 47K on the arm side of the pot opened. Else the pot was the only thing that kept this section stable - else the resistor that 10K would shunt all the 8 volt buss feed into the part and the gate would blow from latching on - not because the gate was high, just that the bias resistor setting being that high - made the part latch when you applied power and poof...so you couldn't let those pots move even with the slightest amount of dirt can upset the divider and you wound up having to order another RDHHF1 because the pot wiper resistance when dirty - jumped way too high and blew that part.

Information contained below is outdated material (Circa. 2008) - but may prove useful for troubleshooting...Use of the information is your own personal liability....

Theses are just notes on how I got the 150 to work (condensed) - you're mileage may vary...

I just followed the 1K leader as kept the chip resistor in there too. The 150 was mostly class C anyways so bias didn't matter all that much - the 1K resistor with the other missing one in operation seemed stable to a degree - the Class was ok, just you didn't mess with the RV part else the wiper arm resistance to ground would wipe out the transistor.

Placing the diode in there, in AM or FM like the thing had - only rectified the 1K to ground and didn't hurt it as long as you re-tweaked RV21 to keep the bias - when you put the 1K in there WITH the diode - you had to adjust RV21 to a different range - you kinda set watts on the darn thing this way. That's when I found out about RV21 going bad - the shorted leads across two terminals

Once you put the parts in there (resistor - not the diode you are correct)- there was not all that much else you had to do - just adjust RV 21 (ON LOW) to obtain the drive bias by watching the power meter - audio was set right when you reduce the swing and the parts stayed cool to the touch (Carrier came up or went down depending on the way you had set RV21 - then when done you went back and re-set the AM power and FM power by DIRECT watts on the power meter

I might have some more notes about those two type of radios - the 150 could have done better and with the "class C" biasing and recitifier - Bro had a radio back...The 200 required some expsenive parts

The above was all done without a schematic on the fly with the brother breathing down my neck - so when the schematics showed up at least I had some references - so again the above is steps I took to make a 150 work...

Will look around some more...