When someone posts that his radio has no receive, or no transmit it's easy to assume that there is just one fault behind this failure.

When a radio has no transmit AND no receive, this points to a fault in a circuit shared by both the radio's receiever and transmit circuits.

But sometimes it's NOT just one failure.

This 1995 Uniden Washington was totally deaf, and had no transmit power at all. A look at the green/red LED on the front shows red when the mike is keyed. This tells you that the PLL is not out of lock. A look with the 'scope at the output from the PLL showed that the signal level was incredibly weak. That will do it.

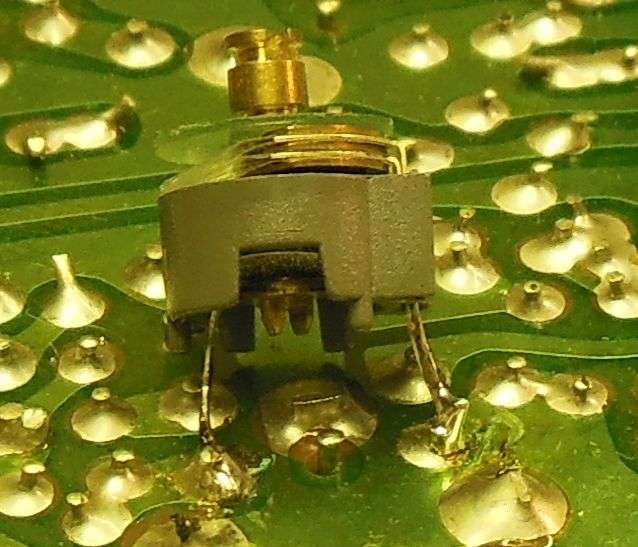

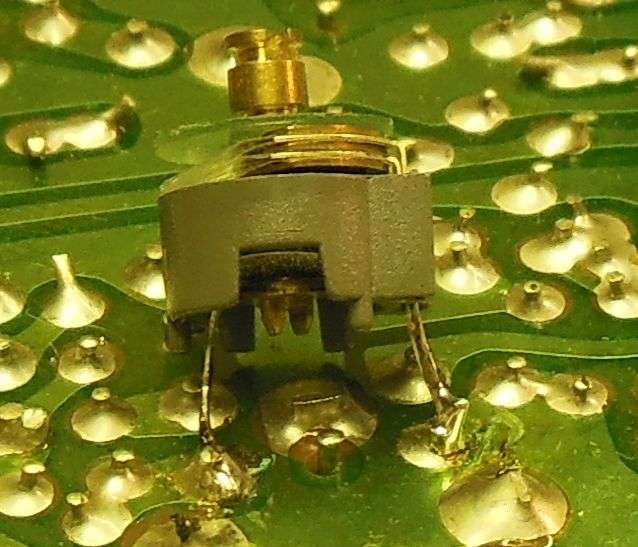

The output coil L14 from the PLL branches off feeding into the transmit mixer and the receiver mixer. A look with the 'scope showed a peak with the tuning slug DEAD EVEN with the rim of the hole in the top of the can. This is a clue that the capacitor inside that coil has died. The apparent peak at this "flush" position is not really a peak. Just looked like one. And the output level from L14 was still really weak. Sure, plucking L14 out and replacing it with a new one will fix this failure, but there is a more-economical hack. Replace the function of the failed internal capacitor with an external trimmer cap, soldered across the two pins of L14 where the internal cap is connected.

With the trimmer adjusted to take the place of the failed internal cap, the slug of L14 now showed a proper peak, about three turns of the slug below the rim of the hole in L14.

Just one problem. Still no receive and no transmit.

Long story short, I found FIVE more slug-tuned coils with this problem.

One at a time.

Once every slug in the radio exhibited a proper resonant peak on the tuning slug, it came completely back to life.

Just goes to show that sometimes it's not "just one" thing that has failed in a dead radio.

73

When a radio has no transmit AND no receive, this points to a fault in a circuit shared by both the radio's receiever and transmit circuits.

But sometimes it's NOT just one failure.

This 1995 Uniden Washington was totally deaf, and had no transmit power at all. A look at the green/red LED on the front shows red when the mike is keyed. This tells you that the PLL is not out of lock. A look with the 'scope at the output from the PLL showed that the signal level was incredibly weak. That will do it.

The output coil L14 from the PLL branches off feeding into the transmit mixer and the receiver mixer. A look with the 'scope showed a peak with the tuning slug DEAD EVEN with the rim of the hole in the top of the can. This is a clue that the capacitor inside that coil has died. The apparent peak at this "flush" position is not really a peak. Just looked like one. And the output level from L14 was still really weak. Sure, plucking L14 out and replacing it with a new one will fix this failure, but there is a more-economical hack. Replace the function of the failed internal capacitor with an external trimmer cap, soldered across the two pins of L14 where the internal cap is connected.

With the trimmer adjusted to take the place of the failed internal cap, the slug of L14 now showed a proper peak, about three turns of the slug below the rim of the hole in L14.

Just one problem. Still no receive and no transmit.

Long story short, I found FIVE more slug-tuned coils with this problem.

One at a time.

Once every slug in the radio exhibited a proper resonant peak on the tuning slug, it came completely back to life.

Just goes to show that sometimes it's not "just one" thing that has failed in a dead radio.

73