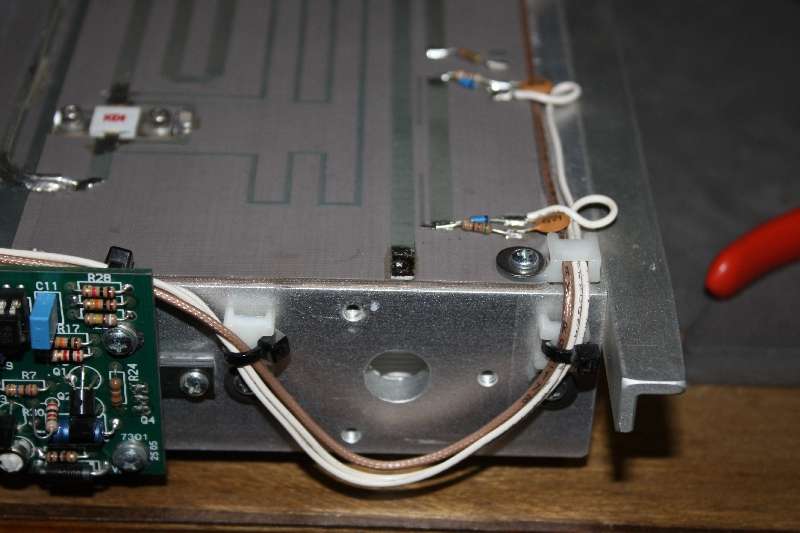

Well I finally got around to getting a bit of work done on the Larcan module. I needed to change the proprietary input/output connectors on the module to something a bit more useful. The input connector looked somewhat like a flared BNC connector as can be seen on the left below.

It was replaced with a simple BNC connector. RF power at this point is only in the order of 10-12 watts so power handling was not a factor and a BNC will do nicely.

The output connector posed a bit more of a challenge especially if one did not want to simply hack off the old connector and mount a new connector on an L bracket and call it done.

I decided to see if I could adapt the existing connector to accept either a type N connector or better yet an SO-239. I say "better yet" as the SO-239 is still quite acceptable for use at 50 MHz and the center pin is more robust and will handle more connect/disconnect cycles than an N connector as well as handle more RF power. This point will have as much as 1200 watts so having a good connection is mandatory. I started by removing the original connector and taking it apart. I noticed that an SO-239 chassis connector will almost fit inside the original connector and if a washer of the proper size was found it could be made to fit by inserting it from the rear of the connector and it could be held in place by abutting against a flange in the connector towards the front and by using the large silver plated threaded ring screwed in from the rear to hold everything in place.Below are the parts I had to work with showing the connector body and large clamp ring on the left as well as two pieces of PC board material used with the original connector on the bottom. The pieces on the right of the picture are what I had to make or salvage.

I needed a washer that the SO-239 chassis connector would fit inside of while the outside would in turn fit inside the original connector. The closest I could come up with was a 12mm washer that I had tons of at work although a 1/2 inch would work just as well. The 12mm I had was slightly thinner however and easier to work with. I used stainless steel BTW as it is not good practice to use ferris materials to carry high RF currents. I first worked on the outer diameter by installing the washer on a tapered head bolt so that the washer would be centered perfectly. The bolt was then placed in the chuck of a cordless drill. This allowed the washer to spin without a wobble. Next I placed the washer against the wheel of a power sanding disk and while squeezing the drill trigger I slowly ground the washer down to a smaller diameter by having the sanding disk rotate in one direction while the drill spun in the opposite direction. Precision was the name of the day as the flange is very small and taking too much off would make it useless.After getting to fit perfectly I drilled a 5/8 hole in the center to accept the chassis connector. You should work on the outer dimension first as when you drill the center hole any offset from perfect will cause the washer to wobble and make it very hard to achieve a perfectly round adapter.The finished product can be seen immediately to the right of the chassis connector. The other washer and hex nut came with the chassis connector. Here is the result below.

I also need a small bushing to take up the tiny bit of slack as the silver threaded ring would bottom out in the original connector before the adapter was tight. A simple washer made from copper was made as it had to bend somewhat due to the projection of the center rearward into the original connector. It can be seen in the picture above . Here it is in place in the new connector being held in place with the threaded nut. It is important that the nut be seated all the way and is flush with the rear of the original connector and not protrude as this will interfere with mounting later.

This is where it pays to be precise in your measuring and drilling. There is zero clearance for the hex nut. in fact I used the sanding disk to ever so slightly take the points off the nut so it would fit.

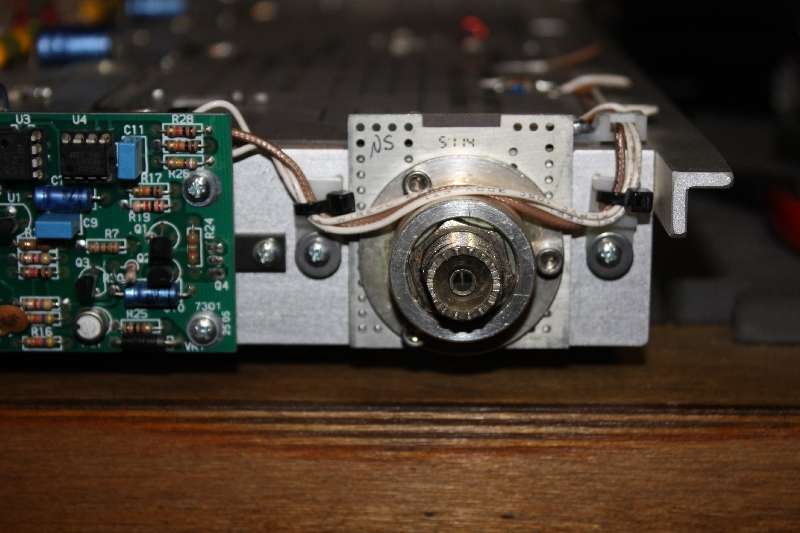

The finished connector mounted on the PC board for final mounting.

Mounting location of output connector.

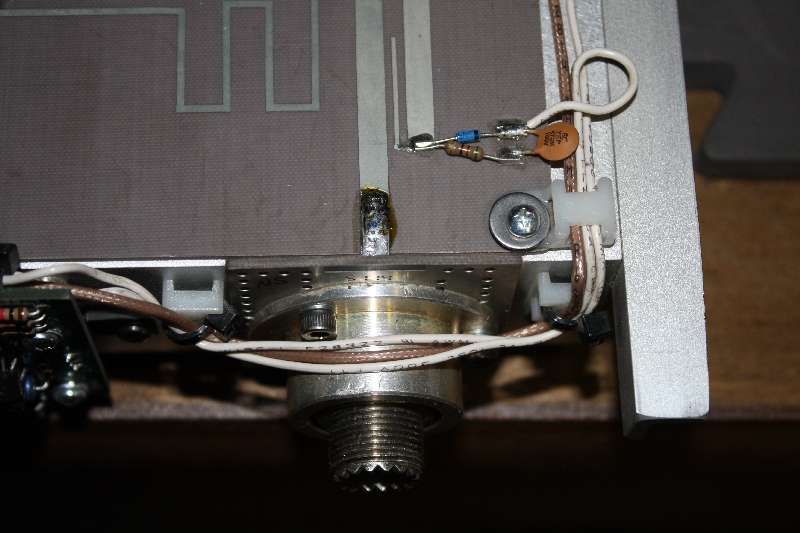

New connector mounted in place.

And soldered.

Overall picture after installation complete.

BTW I did NOT check the new connector for shorts with an ohmmeter before installation.

I used a megger from work instead.

It only uses 500 volts but that is good enough for me. No shorts or excessive leakage was noted.

I decided to try this method of making a new connector as I did not like some others I have seen. they were basically just a chassis connector mounted on an L bracket or a small piece of metal and mounted on stand-offs or spacers. I like the looks of my connector as it somewhat preserves the original looks and at the same time provides a more finished look. Next comes an RF shield for the component side and some sort of cabinet for it.