You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

B

BOOTY MONSTER

Guest

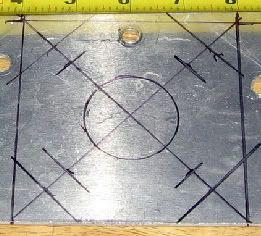

yea , i used to put them under fir and pressure treated 4x4 and 6x6 columns to attach porch rails to and support the roof above . they're aluminum too

and the best part is .............. the hole is already in it

but actually ..... the plate really isn't needed . i had thought of just running the 1 inch strips from tabs for the bottom of the basket radials to split to better contact the vertical pole and strip a chunk or plate with a couple of 45 degree bends a inch apart . a lil tab could hold the stud .

but i like the little plate idea . everything attaches to one solid point with lots of surface area for those connections .

and the best part is .............. the hole is already in it

but actually ..... the plate really isn't needed . i had thought of just running the 1 inch strips from tabs for the bottom of the basket radials to split to better contact the vertical pole and strip a chunk or plate with a couple of 45 degree bends a inch apart . a lil tab could hold the stud .

but i like the little plate idea . everything attaches to one solid point with lots of surface area for those connections .

Last edited by a moderator:

Your clamping things is good, the fewer holes in your tubing the better, I say.

Why didn't you like your original straps for the bottoms of the radials?

Why didn't you like your original straps for the bottoms of the radials?

B

BOOTY MONSTER

Guest

i can still use them and may till i can find a jigsaw to borrow to cut the hole in the plate , or a 1 3/4 - 2 inch hole saw bit that'll cut metal . i noticed how the tubing could possibly pivot at the ring with just a single bolt on each end of it and figured that wasn't a good thing . that's why i changed the tops . on the bottom i wanted the radials more evenly spaced around the center radiator , to be more symmetrical . my original bracket was a bit too large and i'm sure you're aware this stuff doesn't like being tightly bent one direction and then another on or near the same spot . it also provides a great attachment point for the stud coax mount .

just a learn as i go thing . but the plate is the strongest neatest way i can think of doing it with the materials ,tools and limited brain power i have available .

this antenna seems to really like 1/4 wavelengths according to the successful mods . 1/4 wl basket element . maybe some slight barely detectable improvement using a 1/4 wl loop circumference . and SWs' 27 inch gamma tap point is a 1/4 of a 1/4 wl . LOL

i think i might be thinking about this too much

what do you think ?

just a learn as i go thing . but the plate is the strongest neatest way i can think of doing it with the materials ,tools and limited brain power i have available .

this antenna seems to really like 1/4 wavelengths according to the successful mods . 1/4 wl basket element . maybe some slight barely detectable improvement using a 1/4 wl loop circumference . and SWs' 27 inch gamma tap point is a 1/4 of a 1/4 wl . LOL

i think i might be thinking about this too much

what do you think ?

I haven't analyzed the lengths of things like you are doing, but maybe I should! I'm watching while waiting for you to get it in the air to compare your experience to this with mine.

I love the Fact the Booty is not scared to use a glass table top as a work bench!!! :blink: Looking good Booty please keep up the work!

B

BOOTY MONSTER

Guest

I suggest that if you not prepared to test and compare antennas with this new project, then build it just to get it tuned the best you can and don't worry about it working the best it can. Frankly, I don't think you'll be able to tell if it works better or not unless you do some comparisons, because I don't think you've worked much at your new location. I also doubt most of us will ever see, what Bob experienced with his hybrid modified Vector and it looks like it might have been a one time deal maybe. I've see such strange things happen at times while I was watching my antennas respond to different signals, but I consider most of that stuff aberrant and I use greater signal sampling to average such events out of the mix I get and report.

Just making a few comments off the top of my head.

Be sure and let me know if I can help with any dimensions that I might have here.

Good luck, and keep us posted.

i thought i had commented on that earlier , but i apparently didn't . very good and %100 correct OGP . there are a few guys near me with setups that consistently hear better than others . there's also one guy with a set of 3 element beams . i plan to gauge my results with different lengths comparing how my receive compares to theirs . i also plan to try to get meter and audio reports from others farther away to use . ill use those results to find the sweet spot for for the length of the vertical and basket elements for this particular install . if i can tx/rx with %998 + of what everyone else does it'll be a very effective antenna .

B

BOOTY MONSTER

Guest

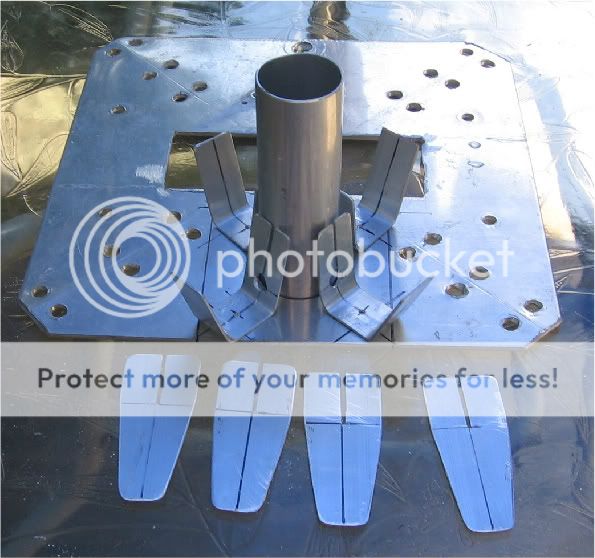

to add to my continuous saga of designing , making and then re-designing and re-making as i go along .........

as has been suggested in other threads on this forum i'm gonna order more tubing later to double wall the two bottom sections . so i'm gonna make the hole in the plate bigger . im also gonna make the pieces that connect to the main vertical and the basket elements at the bottom one piece that connects to the plate . i made both them and the top brackets for the loop and basket elements today , this is what they looks like ....

the 4 tabs in front are for the ring .

the 4 on the plate are bent enough to show how it goes together . im not gonna cut the plate till i get the big hole in it . got to get back over my buds house to use his hole saw get some aluminium tape . then i can finally get the thing together and see if im a genius or an idiot .

BTW , i've been called many things , but genius isn't on that list . :headbang

as has been suggested in other threads on this forum i'm gonna order more tubing later to double wall the two bottom sections . so i'm gonna make the hole in the plate bigger . im also gonna make the pieces that connect to the main vertical and the basket elements at the bottom one piece that connects to the plate . i made both them and the top brackets for the loop and basket elements today , this is what they looks like ....

the 4 tabs in front are for the ring .

the 4 on the plate are bent enough to show how it goes together . im not gonna cut the plate till i get the big hole in it . got to get back over my buds house to use his hole saw get some aluminium tape . then i can finally get the thing together and see if im a genius or an idiot .

BTW , i've been called many things , but genius isn't on that list . :headbang

Last edited by a moderator:

Looks good, Booty. I'm guessing you're going to put the so-239 connector between two of the angles on the flat plate.

B

BOOTY MONSTER

Guest

yep , im trying to keep it symmetrical , small and strong . im gonna do like you and use a mobile stud mount . there's a 3/8 hole on the leg of the 5/8 gamma tube and of course the SS 3/8x24 bolt to hold them together . the middle of the bottom of the basket elements will be about 1 inch off the side of the main vertical . 2 hose clamps will hold the split tops to the vertical . when everything is finally like i want it to be at the hub it'll be taken apart , cleaned/sanded and reassembled with noalox then sealed with permatex .

Sounds like a plan. If your antenna works equal to your planning and doing it'll be the only vertical to ever out perform a big Yagi!

booty, not sure if you are past this point yet or not, but i wanted to remind you that you dont need to use tools made for cutting metal when using aluminum.

a hole saw made for wood will cut aluminum just fine.

just use a bit of cutting oil to keep the friction down.

the problem with using carbide tools made for cutting steel is that the aluminum shavings will actually melt onto the blade/bit/wheel and gum it up.

also, im wondering if you plan on attaching the hoop to the vertical radiator using some sort of insulating material such as fiberglass or UV resistant plastic.

this will keep the vertical radiator centered in the hoop and effectively reduce the amount of sway.

i believe that if more people had done this to their sigma type antennas, there would be far fewer stories of them breaking in the wind.

(LOL, i said breaking in the wind)

LC

a hole saw made for wood will cut aluminum just fine.

just use a bit of cutting oil to keep the friction down.

the problem with using carbide tools made for cutting steel is that the aluminum shavings will actually melt onto the blade/bit/wheel and gum it up.

also, im wondering if you plan on attaching the hoop to the vertical radiator using some sort of insulating material such as fiberglass or UV resistant plastic.

this will keep the vertical radiator centered in the hoop and effectively reduce the amount of sway.

i believe that if more people had done this to their sigma type antennas, there would be far fewer stories of them breaking in the wind.

(LOL, i said breaking in the wind)

LC

B

BOOTY MONSTER

Guest

i hole saw is what im going to use . i've still got my old 1/2 inc makita 120v drill . i got a line on borrowing a 2 1/8 inch one in the next day or 3 so ill keep the $14 and borrow that . Bi-Metal is whats needed .

LOL i said Bi

i was going to use the plastic lumber x on the hoop and ring . but ive figured out a way to drop it down to about 4 feet below the hoop .

"If your antenna works equal to your planning and doing it'll be the only vertical to ever out perform a big Yagi!"

at least stacked 8's

dxChat

- No one is chatting at the moment.

-

@ Hambones amps:Does anyone know if you can replace the 2290 in a galaxy dx 93t twin turbine with a 2sc2879 red dot? If so, what would have to be tuned?

-

-

@ ShadowDelaware:Hambones the entire amp section would have to be retuned, and the rf transformers re wrapped.