I have a Robyn 520D that I am working on now. The gentleman stated that he put it up 12 years ago working and when he fired it up recently it didn't work. So when I started here is what I got..

Extremely low receive-AM/LSB/USB but you can hear the hiss increase with the volume. I have to turn the volume all the way up to hear a station that is 2 miles away that normally hits with +10. Also checked with external speaker with same results. There is no reading on the S-meter, meter does work.

Transmit-

AM -1.5w on external meter will not increase or decrease when adjusting vr for AM stays the same. With modulation into the mic it has a slight negative swing. I can talk to station that is about a half mile away and he can hear and understand me.

LSB/USB - no power on key up, extremely low output less than half a watt with modulation. RX is better than AM but still extremely low.

So I started with a recap..

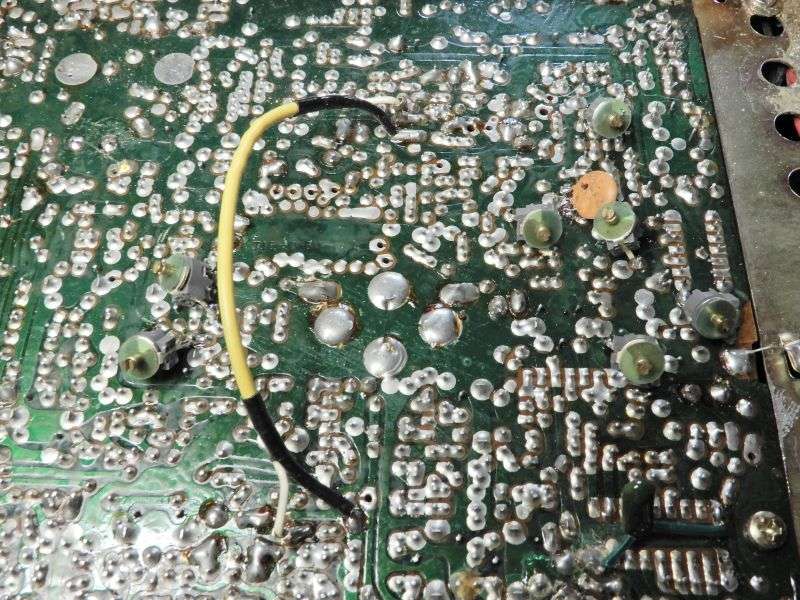

I recapped all the electrolytic caps and c179.

Pulled and checked pre driver/driver/final...all check good.

Rx volume is still the same and Tx modulation still the same. When checking on an external modulation meter I am getting around 20%

I am newer at this and I can go thru the schematic and check each part one by one but if I was more seasoned I would know where to start looking first. What I think if I am correct the audio chip is ok its voltage are consistent with the book and the PA section works and is very loud. The low receive and no Tx modulation I am assuming to be related?

Any help on where to start would be greatly appreciated.

73

Richard

Extremely low receive-AM/LSB/USB but you can hear the hiss increase with the volume. I have to turn the volume all the way up to hear a station that is 2 miles away that normally hits with +10. Also checked with external speaker with same results. There is no reading on the S-meter, meter does work.

Transmit-

AM -1.5w on external meter will not increase or decrease when adjusting vr for AM stays the same. With modulation into the mic it has a slight negative swing. I can talk to station that is about a half mile away and he can hear and understand me.

LSB/USB - no power on key up, extremely low output less than half a watt with modulation. RX is better than AM but still extremely low.

So I started with a recap..

I recapped all the electrolytic caps and c179.

Pulled and checked pre driver/driver/final...all check good.

Rx volume is still the same and Tx modulation still the same. When checking on an external modulation meter I am getting around 20%

I am newer at this and I can go thru the schematic and check each part one by one but if I was more seasoned I would know where to start looking first. What I think if I am correct the audio chip is ok its voltage are consistent with the book and the PA section works and is very loud. The low receive and no Tx modulation I am assuming to be related?

Any help on where to start would be greatly appreciated.

73

Richard